NITTO EPTSEALER NO.6800 Series

Retail Price

Market price

Weight

kg

Inventory

隐藏域元素占位

NITTO EPTSEALER NO.6800 Series

A foam sealing material rich in softness and elasticity, independent foam structure, weather resistance, and watertightness. It is a high-performance foam made by independent foaming of EPDM mixture with high durability and weather resistance in general-purpose rubber. The NO.6800 series can be bonded with butyl rubber adhesive or acrylic adhesive according to the needs of customers, so as to correspond to various applications.

Classification:

Cushioning Material

keywords:filters

- Details

- Product parameters

- Applications

-

Features:

1. Good weather resistance and water tightness, stronger heat resistance than polyurethane or polyethylene and other foaming waterproof materials

2. EM-142 uses butyl rubber adhesive, which has strong adhesion to rough surfaces

3. No.681, No.6801, and No.6801P use acrylic adhesives, which have excellent retention, heat resistance, and weather resistance. 4. Independent cell type, good flexibility and elasticity. 5. Even

for complex shapes The gap can also be easily constructed

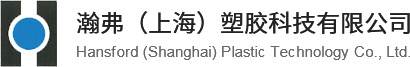

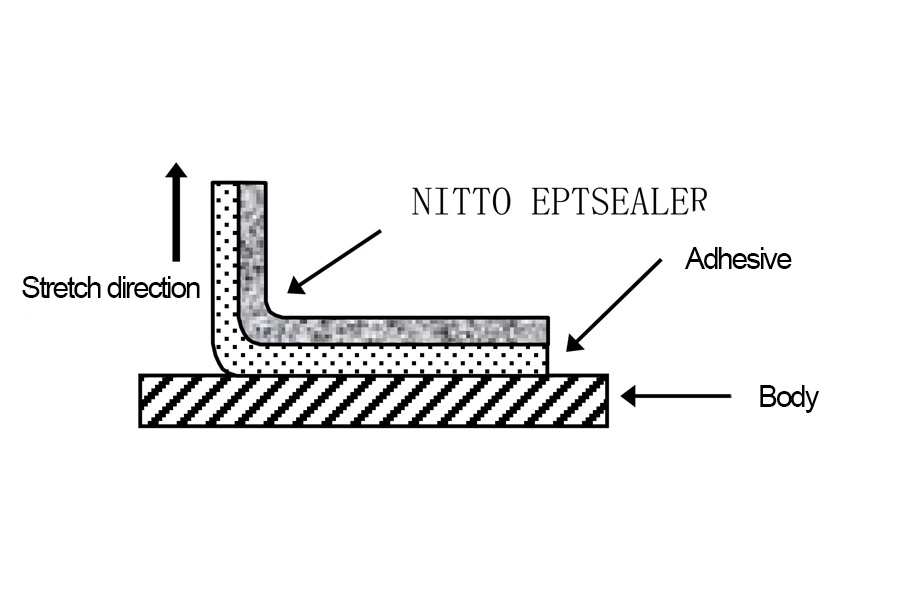

structure:

Precautions:

1. Please fully clean up the oil, water and dust on the surface of the body to be applied.

2. When cutting NITTOEPTSEALER using acrylic adhesive (substrate: non-woven fabric), process it in parallel to the length direction. Please note that if processed in the width direction, stretching may occur during use.

3. When cutting NITTOEPTSEALER with butyl rubber-based adhesive, please process it parallel to the length direction or width direction. Please note that if it is processed at an angle, it may expand and contract during use.

4. The adhesive layer is pressure sensitive, please fully press it when pasting.

5. The temperature of the paste operation environment should be above 10°C. (In winter, when the temperature is lower than 10°C, the initial adhesive force will decrease.)

6. Please store the coiled product horizontally to prevent deformation.

7. Please avoid storing in a dark place with high temperature and humidity and not exposed to direct sunlight. -

Standard size:

Thickness (mm)

Width (mm)

length (m)

3~15

1000

2

characteristic:

According to JIS K 6767

product name

Appearance density

(g/cm3)Tensile strength

(N/cm2)Extension

(%)Compression hardness (N/cm2 )

25%

50%

NO.6800

0.12

35

240

2.5

8.0

※The data above is only an example of measured values, not guaranteed values.

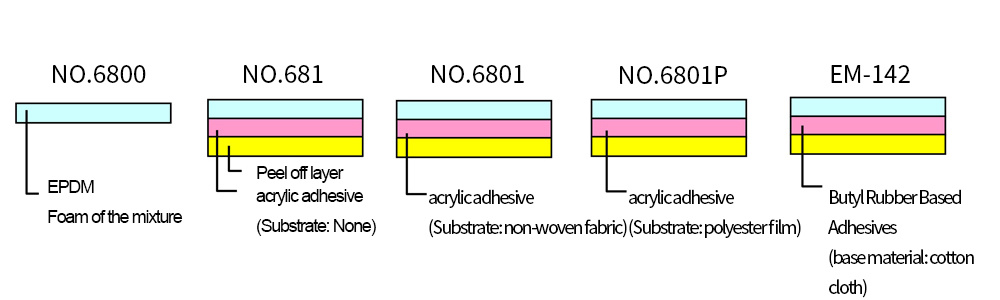

●Relationship between compressibility of foam and compressive hardness

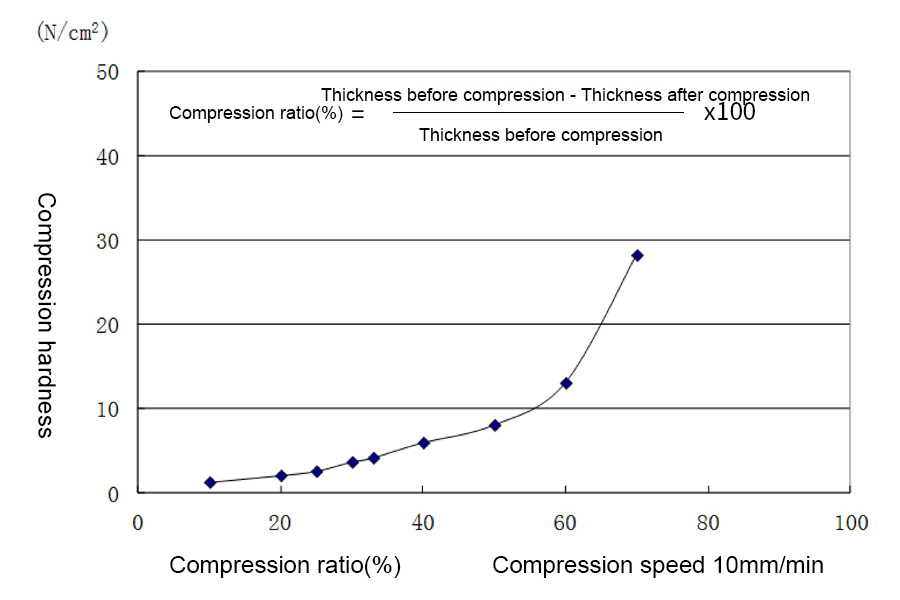

●Relationship between compressibility of foam and water tightnessCompression ratio(%)

NO.6800

0

x

10

△

25

○

50

○

○: No water leakage after 30 minutes

△: Water leakage within 30 minutes

×: Water leakage within 10 minutes

Test method

Clamp each sample with a 10mm wide perforated board,

compress and fix it according to the specified thickness.

Add water to a depth of 100mm and check for water leakage.

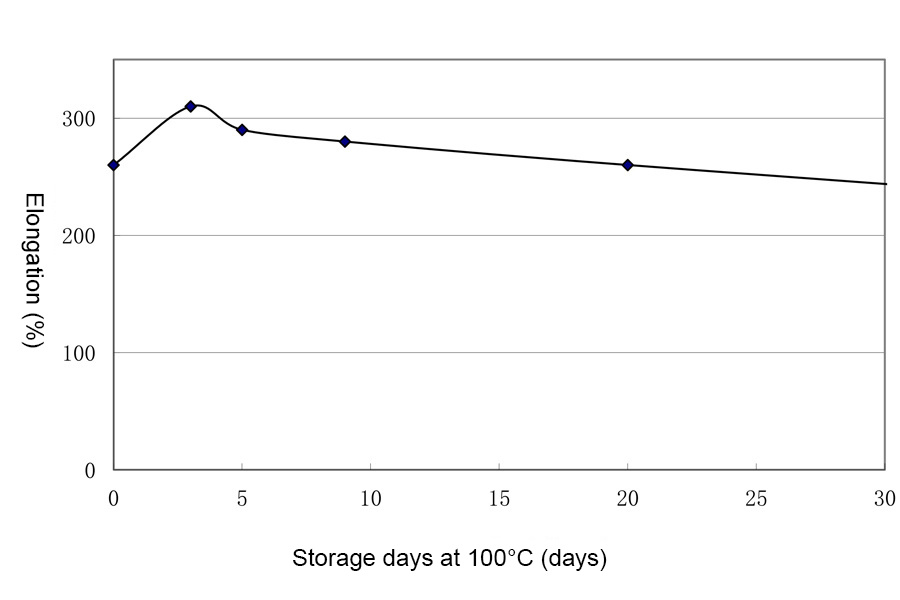

●Heat resistance (change in elongation of foam after being placed in an environment of 100°C)

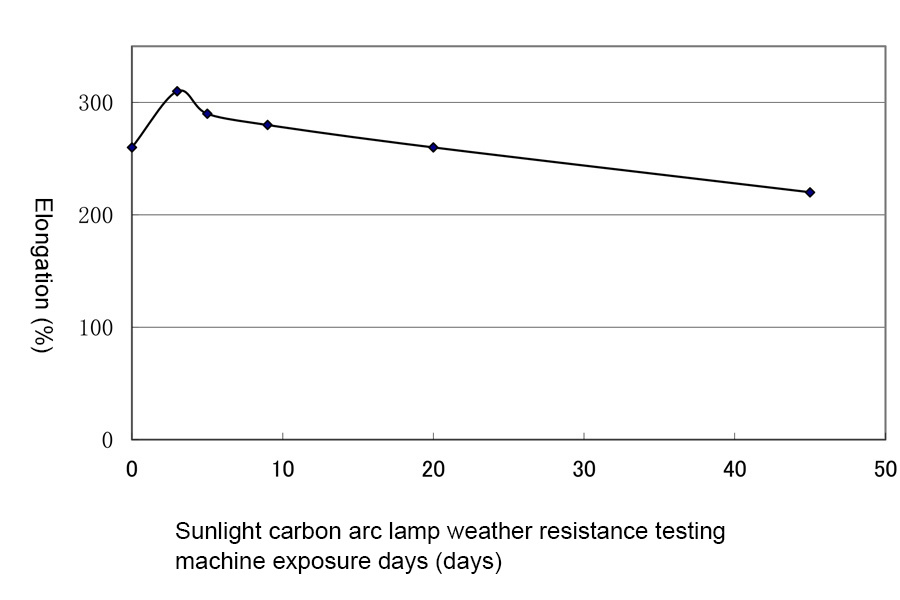

●Weather resistance (change in elongation of foam after UV aging)

●Adhesion (90°peel)NITTO EPTSEALER

NO.681

NO.6801

NO.6801P

EM-142

Adhesion (N/15mm)

5.7

7.2

6.8

12.0

Use a 2kg roller to press back and forth once on the coated stainless steel plate. After standing for 30 minutes,

measure the peeling adhesion at a speed of 300mm/min. The measured temperature was 23°C.

-

Application:

1. Sealing of the sticking part of the air conditioner box

2. The part requiring a high waterproof effect

3. The installation part of the skylight

Previous Page

Next Page

online message

Filling in your phone and E-mail information will help us to contact you in time and solve your problem as soon as possible.