High viscosity, high adhesion, new double-sided tape (solvent-free) 518/5185 series

Retail Price

Market price

Weight

kg

Inventory

隐藏域元素占位

High viscosity, high adhesion, new double-sided tape (solvent-free) 518/5185 series

NITTO DENKO has developed TEMISH™ porous PTFE (polytetrafluoroethylene) through its own processing technology. TEMISH has millions of micropores per square centimeter, so it is highly breathable.

Classification:

Sticky Tape

keywords:filters

- Details

- Product parameters

- Applications

-

(Nitto) Solvent-free technology ①If

an organic solvent is used, there will be a small amount of solvent remaining in the tape, which may produce an unpleasant and harmful smell to health after volatilization. Nitto's low-VOC double-sided tape does not have the above-mentioned problems because it uses a latex adhesive.

Latex (Em) Adhesive

(Nitto) Solvent-free technology ②The

low-VOC double-sided tape we refer to is not only a product that does not contain regulated substances, but a tape with a small total amount of VOC. The VOC

emission of low-VOC double-sided tape

is due to the use of Latex adhesive not only has no toluene, but also has very little VOC emissions.

-

Technical data sheet:

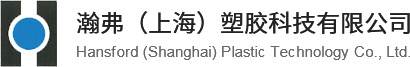

NO.518 Performance comparison report of double-sided adhesive tape.

And the comparative report tape structure of NO.5185 and competing productsItems

NO.518

NO.5185

competitor

structure

adhesive

Acrylic adhesive

(solvent-free type)Acrylic adhesive

(solvent-free type)Acrylic adhesive

(solvent type)Thickness (mm)

0.1mm

0.145mm

0.15mm

Adhesion (N/20㎜)

21.3

25.2

16.8

tape color

colorless

colorless

colorless

The above thickness is measured by a digital measuring instrument, and the above is a measured value, not a guaranteed value. This product is currently in development, so this design is subject to change

Technical Data Sheet:

180 Degree Peel ForceSubstrate

NO.518

NO.5185

competitor

SUS (stainless steel plate)

21.3

25.2

16.8

ABS (plastic)

21.4

24.3

12.7

PCABS (plastic)

21.5

24.9

15.2

PC (plastic)

21.4

24.1

17.7

PP (plastic)

21.1

24.3

16.1

Pst (polystyrene plastic)

21.4

24.7

18.9

AL (aluminum plate)

21.7

25.8

17.5

Acrylic plate

(plexiglass)23.9

28.5

19.5

Glass glass plate

21.4

27.8

15.7

PE (plastic)

twenty two

28.1

13.1

The above thickness is measured by a digital measuring instrument.

The above are measured values, not guaranteed values.

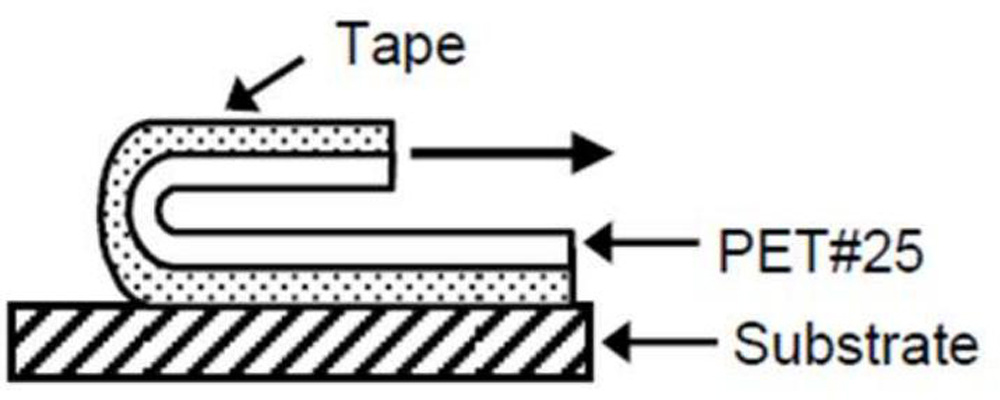

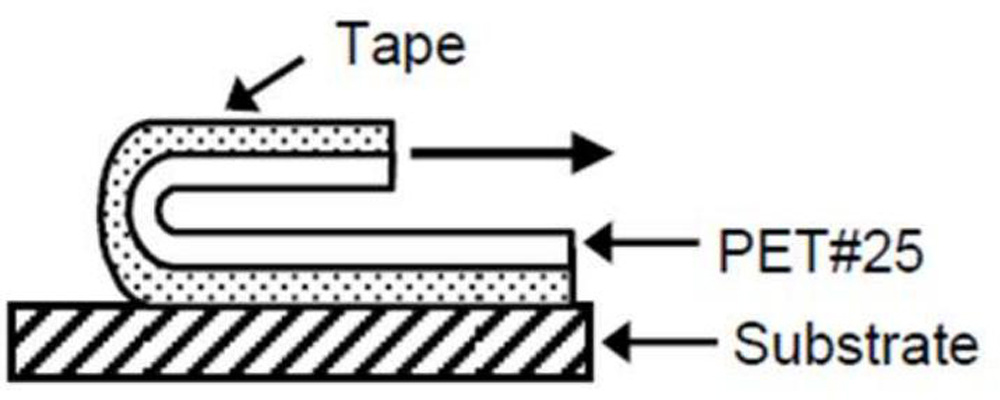

This product is currently in development, so this design is subject to changeBond strength on different substrates

Evaluation method: (Unit: N/20mm)

Backing material: PET#25

Condition: 23degreeC/50%RH

Lamination:2kg roller x 1 pass back

Aging time: 30 min

Peeling angle: 180degree

Peeling speed: 300 mm/min

Technical data sheet:

180 degree peel adhesion to SUS at different temperaturesTemperature

NO.518

NO.5185

competitor

23°C

21.3

25.2

16.8

40℃

19.7

23.1

15.9

60℃

10.8

12

9.5

Evaluation method: (Unit: N/20mm)

Backing material: PET#25

Substrate: SUS

Condition: 23degreeC/50%RH

Lamination: 2 kg roller x 1 pass back

Aging time: 30 minutes

or more The thickness is measured by a digital measuring instrument, the above is Measured values, not guaranteed values. This product is currently in development, so this design is subject to changeAdhesive strength to SUS at different temperatures

Technical data sheet:

Anti-peel resistance for individual plastic panelsSubstrate

NO.518

NO.5185

competitor

ABS

1

1

tilt up

PP

1

1

tilt up

Pst

1

2

tilt up

(Unit: mm/72Hr)

AL plate: 20mm x 180mm

Substrate size: 30mm x 200mm

Repulsion condition: Laminate a substrate and AL plate with tape by laminating machine.

Fit the left sample into wooden mold then leave it at 70 degree C x 72 Hrs and measure

the floating height.

The above thickness is measured by a digital measuring instrument.

The above are measured values, not guaranteed values.

This product is currently in development, so this design is subject to change -

Applications:

Around KYEBORD for TVs and notebook computers, Switch nameplates and decorative sheets for home appliances (air conditioners) (toilets), etc., fixing heat insulation materials for refrigerators, etc.

online message

Filling in your phone and E-mail information will help us to contact you in time and solve your problem as soon as possible.