Surface protection material SPV-AM-500

Retail Price

Market price

Weight

kg

Inventory

隐藏域元素占位

Surface protection material SPV-AM-500

It has excellent performance in punching and bending, and can be used as a surface protection material for metal plates. SPV-AM-500 is a special film-based surface protection material for sheet metal processing. SPV-AM-500 can be used for press processing (NCT) and laser processing.

Classification:

Protective Material

keywords:filters

- Details

- Product parameters

- Applications

-

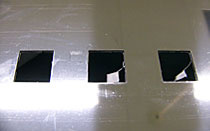

【punch】

AM-500

traditional products

※Small slices

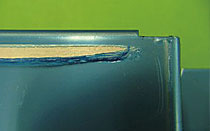

【Curvature】

AM-500

traditional products

※The degree of tearing of the adherend and the degree of SUS scratching are extremely low.

•Prevents chipping when the surface protection tape is thick.

•Almost no chlorine gas is emitted during the incineration process, such as the gas produced when incinerating polyvinyl chloride film.

• When processing metal sheets, the film has good strength and bending workability. -

Characteristic:

product number

Thickness [mm] *1

Adhesive strength [N/20 mm]*2

SPV-AM-500

0.050

1.50

[Replenish]

*1: Nominal thickness

[Test Methods]

*2: Peeling speed: 300 mm/min, peeling angle: 180°

-

Application:

For surface protection when machining sheet metal.

Precautions:

•Avoid direct sunlight and store at room temperature and normal humidity.

• Do not press hard when using, otherwise the end of the tape may be peeled off.

• If using on an oil-treated surface, carefully degrease the surface. Because oil stains will cause the surface of the adherend to be stained or adhesive residue.

• When using under extreme conditions, please conduct a comprehensive test and evaluation of the product in advance.

• After peeling the tape, a small amount of adhesive residue may affect surface coloring, plating, etching or bonding. Before application, check thoroughly under actual conditions.

• Depending on conditions such as paint bake, the painted board may not peel off the tape easily or may peel off together with the paint. Please do a full assessment beforehand.

•Surface-treated boards, such as anodized aluminum, may have different SPV (peeling) characteristics depending on the treatment conditions. Please do a full assessment beforehand.

• Especially for applications on natural substrates (marble, wood, etc.), please contact our sales representatives.

•The data in the above data sheets are measured values under specific test conditions, and actual performance is not guaranteed.

•Product quality, performance and/or functionality may vary depending on conditions of use. Please contact our competent department for detailed information on this product.

•Under extreme conditions, there may be a difference between sample measurements and actual performance of this product. In consideration of your own safety and product performance, please test and evaluate the product thoroughly.

• This product and/or its features are subject to change or discontinuation without prior notice.

online message

Filling in your phone and E-mail information will help us to contact you in time and solve your problem as soon as possible.